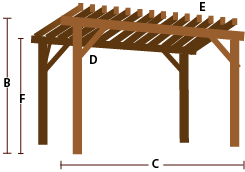

| SIZES | 10′ | 12′ | 14′ | 16′ | 18′ | 20′ | 24′ | NOTES |

|---|---|---|---|---|---|---|---|---|

| A | 12’8″ | 14’8″ | 16’8″ | 18’8″ | 20’8″ | 22’8″ | 26’8″ | Outside of roof to outside of roof. Standard overhang is 16″ |

| B | 9’7″ | 9’7″ | 9’7″ | 9’7″ | 9’7″ | 9’7″ | 9’7″ | Overall height |

| C | 10′ | 12′ | 14′ | 16′ | 18′ | 20′ | 24′ | Outside of post to outside of post |

| D | Brace size (available in 2′, 2′ 6″, 3′) | |||||||

| E | Header end detail. | |||||||

| F | 8′ standard post length. Post length = distance to bottom of header |

A. Our pergolas and pavilions are completely customized so they can fit over new or existing patios.

A. A pavilion has a roof while a pergola does not, making a pavilion a more versatile choice for climbing plants.

A. Because of our pre-cutting process, we may only be on your property for one or two days. Depending on the intricacy of the customization, it will take longer, but construction will rarely take longer than 4 days.

A. Most counties require a building permit and lot improvement permit for any structure larger than 200 square feet. However, permitting varies from county to county. Brookside recommends checking with your local county for planning and zoning assistance.

The time-honored tradition of timber framing is a building method that goes back thousands of years. Basically, it involves cutting large timbers to the precise sizes that are needed and then carving corresponding sections in these timbers so they fit together. Imagine huge 3D puzzle pieces or a glove and a hand, and you’re pretty close to the theory of timber framing.

Then, instead of typical hardware, like screws and nails, we use wooden pegs in our timber frames. This adds a dimension of strength and rigidity to our timber frame structures.

There are many types of joinery in timber framing. Here are the three main joints we use in our structures:

The mortise is a hole cut into one piece of wood, while the tenon is a projection on the other piece that fits into the mortise. When correctly crafted, a mortise and tenon joint is among the strongest and most durable wood joints.

The Y-shaped pieces in the pictures of our structures are part of the knee brace joint. Notches in the horizontal and vertical beams correspond with projections in the 2 wooden “arms” of the “Y.” This joint strengthens the frame and helps it stand up to wind-loading.

A tongue and groove joint is the joint used in our ceilings and floors to connect each board to the next. Each wooden flat board has a slot on one long side and a ridge on its other long side. The ridge (tongue) clicks into the slot (groove) of the board beside it, creating a keen fit over a wide surface.